Emerging Objects

Rael San Fratello Architects launches emerging objects, a pioneering design and research company that specializes in designing and 3D printing objects for the built environment. Our research and designs focus on the development of innovative 3D printed objects that serve the fields of architecture, interior design, furniture design and product design. Design research will serve as the foundation for this consulting practice with the aim to work with a range of industrial partners, companies, nonprofit foundations and creative practices.

www.emergingobjects.com

Wood, Salt and Wonder

Gizmodo, the go-to authority for gadget news and digital culture, covers our spin-off project, Emerging Objects.

Rapid Manufacturing and Prototyping with Concrete

Earthscrapers is an installation for the 2010 Biennial of the Americas that imagines the potential of employing Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) processes in the construction of a proto-architectural landscape—one where the building material source and the building itself are seamless. It also demonstrates the internal design, research and experimentation process by Rael San Fratello Architects in hacking a 3D printer to rapid prototype and rapid manufacture clays, ceramics and ultimately cement.

Display table demonstrating the tools and outcomes of rapid manufacturing and rapid prototyping with concrete

A rapid manufactured concrete tower maquette

Mining, desertification, dredging and erosion are a few of the many examples of natural and anthropogenic processes for shaping the landscape and have become the theoretical material sources, sites and contexts for the forms and spaces created.

Full scale wall prototype constructed of rapid manufactured concrete masonry units

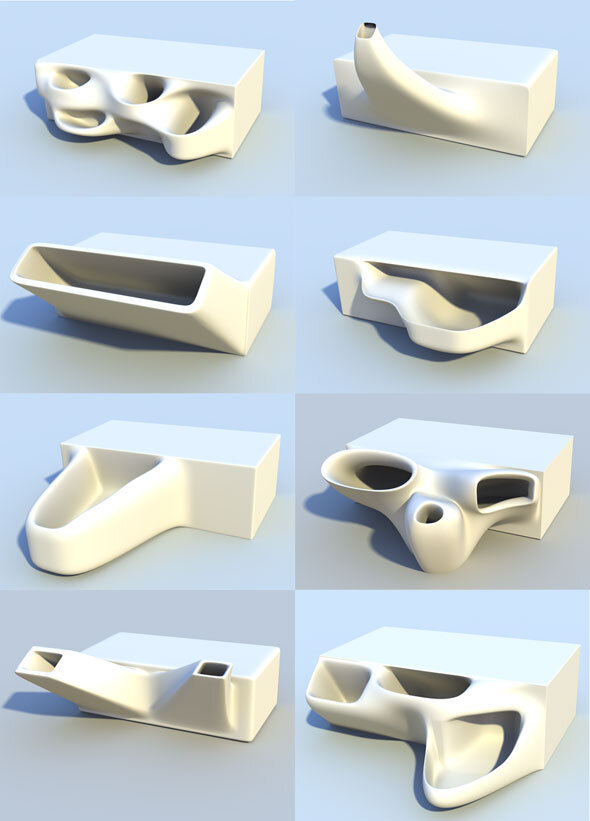

Studies, animations, sketches, scale models and full-scale concrete architectural building components, designed primarily with modo, are the result of the open-ended and open-faced investigation. The project also imagines a future scenario for the material and the process as a scalable technology—one that also dissolves the role of the architect and builder—where designer and geomorphologist merge.

Tools, models and powdered material used in the fabrication of Earthscrapers

linear and vertical modularity using rapid manufactured concrete

3D printed concrete form

Project Date: 2010

Project Team: Ronald Rael, Virginia San Fratello, John Faichney, Maricela Chan, Chris DeHenzel & Emily Licht

Project Info: Earthscrapers was made possible with a grant from 2010 Biennial of the Americas and is on display as part of the exhibit The Nature of Things from July 1, 2010 through August 1, 2010 at the McNichols Building at Civic Center Park, Denver, CO. Special thanks to Ehren Tool, Professor Richard Shaw, Professor Dr. Mark Ganter at the Solheim RP/RM Lab, Pax at MediumVFX and Luxology. 1, 2, 3

Earthscrapers at the Wurster Gallery

Earthscrapers: Rapid Manufacturing and Prototyping with Concrete will be on display in the Wurster Gallery, located in Wurster Hall at the University of California at Berkeley October 4–November 5, 2010 with a Gallery opening Wednesday, October 6th at 7:00pm. The exhibit will feature a presentation of the tools and outcomes of rapid manufacturing and rapid prototyping by hacking a 3D printer to use clays, ceramics, and cement. For more information visit: http://www.rael-sanfratello.com/?p=916

Earthscrapers was made possible with the support and assistance of The 2010 Biennial of the Americas, Luxology (makers of modo), Ceramicist Ehren Tool, Professor Richard Shaw, Professor Dr. Mark Ganter at the Solheim RP/RM Lab and Pax at MediumVFX .

3D/DC

Ronald Rael will present research in the fabrication of concrete and ceramic building components at 3D/DC, an event that will introduce the 3D printing community to the DC policy community, and explore some of the policy issues that this disruptive technology will implicate.

Digital Ceramics

Earth Architecture (Princeton Architectural Press 2008) presents the most widely used building material on the planet—earth (soil, clay, gravel and sand)—as relevant to contemporary and modern architecture and dissolves preconceptions that it is a fragile material in use only in poorer, developing nations.

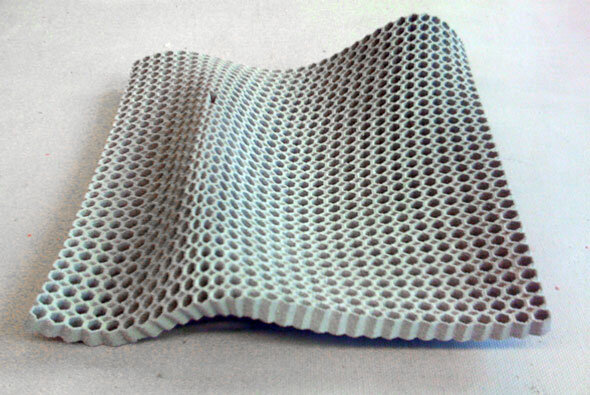

Geomemetic architectural components

"Green" unfired clay extracted from 3D printer

In the book’s afterword, a future scenario for the material is posed—one that employs Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) processes. While it is commonly considered that digital manufacturing and earthen architecture exist at opposing ends of the technological spectrum, this research bridges the wide gap that exists between non-industrial, industrial and digital modes of production expanding on the benefits of each.

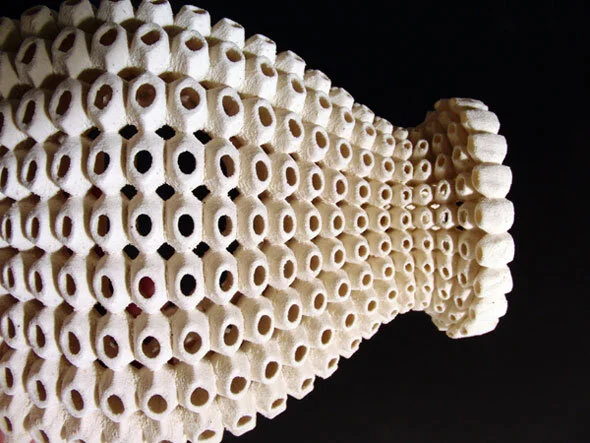

3D printed ceramic offers detail unachievable through traditional processes

Because the inherent nature of 3D printing opens new possibilities for shaping materials, the process of 3D printing clay reshapes the way we think about architectural building components. Digital materiality, a term coined by Italian and Swiss architects Fabio Gramazio and Matthias Kohler, describes materiality increasingly enriched with digital characteristics where data, material, programming and construction are interwoven and this research seeks to exploit this potential by creating ceramic architectural components.

Glazed ceramic print

Working with a research collaborator, Dr. Mark Ganter, of the Solheim Lab in the Department of Mechanical Engineering at the University of Washington, as well as with the collaboration of the Department of Art Practice’s experience with Kilns, clay bodies and mixing techniques, this critical research opens doors to the production of geomemetic architectural components that are weather proof, solar responsive, store or filter water, hold plant life, contain embedded technologies, create insulation barriers between interior and exterior surfaces, dissipate seismic forces and many other possibilities offered by this nascent and potent process. These include prototypes of new brick and façade systems to house vertical gardens in urban areas as well as components that absorb and filter water.

3D Printed Ceramic Brick

Because the process requires no dies or molds, ceramic components can now be mass-customized, employing the flexibility of computer-aided manufacturing systems, rather than mass- produced, allowing design parameters to be quickly changed and tested without incurring costs associated with labor and retooling. Thus, the process bypasses several of the steps involved in traditional ceramics production, which include molding, form making, extraction, slip casting, plaster casting, making it possible to go directly from file to fabrication.

Project Date: 2010

Principal Investigator: Ronald Rael

Additional Project Information: Solheim Lab | Dr. Mark Ganter | Science Daily

The Planter Brick

The planter brick wall is designed to be a combination of traditional masonry units combined with units that can hold plants and vegetation. The plants matched with the bricks require little, if any, soil, but they do need water and nutrients.

A vertical garden

A vertical garden

The planter bricks have the potential to counter the heat island effect in big cities through evapotranspiration and pollution conversion and by the light, reflective color of the bricks. Additionally, edible plants such as rosemary and other fragrant herbs with shallow root systems may be planted in the bricks and accessed through openings in the wall. The plants in the bricks will help mediate the temperature of the microclimate surrounding the building, buffer sound and filter the air. The plants held in the planter bricks will be fed water and nutrients through drip irrigation lines that are built into the cavity of the masonry wall.

Embedded drip irrigation system

The indentations in the bricks that allow for irrigation act much like weep holes allowing water and nutrient to move through a network of continuous drip irrigation tubes that run within the cavity of the masonry wall. The water for the irrigation may be pumped up from below or gravity fed from a cistern or water collection device on the roof.

Sedum requires little water and flourishes in the brick

The planter bricks are made by direct digital manufacturing and rapid prototyping technology. Ceramic particles are printed and held together using an organic binder and then fired in a kiln just like traditional bricks. The bricks may be assembled in a load bearing cavity wall condition or installed as a traditional masonry curtain wall would be on a steel or concrete frame building and can be installed new or retrofitted.

Various brick typologies

The planter bricks are 3D printed using direct digital manufacturing . The bricks are modeled in a 3D software application and the digital file is sent directly to the 3D printer for manufacture. This means a very diverse and infinitely unique selection of bricks can be manufactured based on the clients or designers desires for a particular application. The bricks are manufactured with clay instead of more ephemeral powders that are typically used for rapid prototyping . The 3d clay prints are then bisque fired at cone 5 and glazed to make them waterproof.

Rapid manufactured Planter Brick

The oldest bricks date back to around 7500 BC, these were sun dried mud bricks, around the third milliennium, fired bricks were invented. With the invention of the steam engine early brick-making machines used stiff mud which was forced out in long ribbons on a conveyor belt, transferred to moulds and cut by a revolving cutter. Today, as we march into the 21st century armed with new computer aided design (CAD) and computer automated manufacturing (CAM) technologies we can liberate ourselves from the traditional form of the brick without sacrificing any of the functionality of the brick

Project Date: 2009

Project Credits: Ronald Rael, Virginia San Fratello, Molly Reichert

Additional Information: The Planter Brick was exhibited the Exit Art Vertical Gardens exhibit